December 6, 2024

How Our Elements Work – Chase Elements

Chase Sintered Bronze Elements

The patented Chase Filter sintered bronze elements are designed for Oxygen or any gaseous systems. The element design was engineered to specifically limit the occurrence of a fire event in the Oxygen system. One of the benefits is limiting any event that does happen to only the upstream side of the filter. In order to create an increased filtration area the Chase patented fluted design increases the contamination capacity while decreasing the initial pressure differential.

Chase Sintered Bronze Element

Chase Cellulose Filter Cartridge

The Chase pleated cellulose filter cartridges are available in hundreds of sizes and replace the original manufacturer’s offerings in form fit and function. Our media is heat cured for strength and durability. The media is analyzed per ISO specifications to ensure each shipment is at the desired requirement. The hardware is manufactured from anodized aluminum or plated carbon steel. Cellulose elements are a great low-cost option for holding large amounts of contamination and initial system clean-up.

Chase Cellulose Filter Cartridge

Chase Coalescer Elements

Chase Filter coalescing elements come with a wide array of options. The normal coalescing grade elements are manufactured with Borosilicate microfiber glass and PVDF Fluorocarbon resin bond. Our heavy-duty coalescing elements are constructed with borosilicate glass fibers and rayon. Include a corrosion-resistant aluminum epoxy screen. Our Inner and outer layers are made of rayon fibers impregnated with phenolic resin set between these layers is the coalescing layer (borosilicate Microglass). Efficiencies range from 93% to 99.9999% at the 0.3-micron range. The Chase coalescing elements have a two-layer structure. An inner particulate retention layer and outer drainage layer. The coalescing element should have flowed from the inside out.

Chase Coalescer Elements

Chase Water Absorbing Elements

Chase has the ability to add a layer of water-absorbing media to its pleated element offering or most of our spin-on offerings. This media is designed to chemically trap water inside the specially designed layer of absorbent media for removal of water and particulates from petroleum products. . When a cartridge starts reaching its holding load it begins to swell and causes an increase in the differential pressure which signals the operator to change the cartridge.

Chase Water Absorbing Elements

Chase Micro Glass Filters

Chase’s micro-glass cartridge elements are designed for a wide range of fuel, oil, gas and air applications. Our cartridges stand up to static or dynamic applications. Our Beta 1,000 (99.5% efficient) media is laminated on both sides to prevent media migration. It is also supported on both sides to withstand higher-pressure drops and rigorous industrial conditions. We also offer our special high-temperature element option that can handle temperatures to 325 degrees F.

Chase Micro Glass Filters

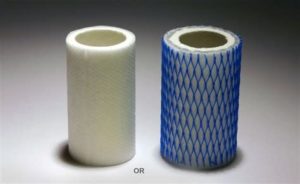

Chase String Wound Elements

Chase Filters string wound elements are manufactured from FDA-listed bleached cotton, standard bleached cotton, natural cotton, FDA-listed polypropylene, standard polypropylene, rayon, polyester, nylon, fiberglass and fibrillated polypropylene. Provide depth filtration and exceptional prices. Center cores are available in tin, 304SS, 316SS and polypropylene. Available micron ratings from 0.5 to 200 microns. Cartridges are available constructed from many different materials offering excellent compatibility with many fluids and temperatures. The string wound cartridges are available in sizes to fit most commercially available housings. Applications: Oil Field Process Water Plating Chemicals, magnetic coatings, Cosmetics, Health Care, Air, Gas, food and beverage

Chase String Wound Elements

Chase Bag Filter Elements

- Micron ratings from 1 to 1500

- All industry standard and custom sizes are available

- Wide chemical compatibility

- Sewn construction

- Handles standard on all bags

- Economical removal of non-deformable contaminants

- Temperature ratings to 350ºF

- Polyester and nylon materials meet FDA regulations for contact under CFR21, section 177.1520

- Silicone-free construction

Chase Bag Filter Elements

Chase Stainless Wire Mesh Elements

Chase’s stainless steel wire mesh elements are available from 10 microns to 100 mesh. We offer all 300 series construction. They can be bonded with either high-temperature epoxy or welded. These elements excel in high temperate and highly corrosive environments.

Chase Stainless Wire Mesh Elements

Chase Fiber Metal Felt Elements

The Chase fiber metal felt offering is a combination of metal fiber, nonwoven media that is produced to match your quality, productivity, handling and maintenance requirements. Consisting of very fine metal fibers of a consistent diameter, fiber metal felt media excels in strength while maintaining a very thin cross-section.

Process control determines the micron rating of the filter media. Fiber metal felt media is typically described by its filtration efficiency. Fiber metal felt is provided in 316/316L and is available in the range of 3 to 100 microns.

Chase Fiber Metal Felt Elements

Chase 316 Sintered Metal Elements

Powdered Sintered Material is a depth-based filtration media. Chase takes small spheres of 316SS in a proprietary mixture that is encased in specialized tooling and heated to form the filter element. These elements are available in 0.2 to 200 microns. They are best suited to air or gas. They also can filter liquids that have lower viscosities.

Chase 316 Sintered Metal Elements