Alternative Fuel Industrial Filters

When you think about filters in an engine, air filters and oil filters may come to mind. There is one filter, however, that few people think about — the fuel filter, which helps keep fuel free of contaminants like rust, scale, dirt and water.

These impurities, which often come from rusty and dirty storage tanks, can plug carburetors and fuel injectors, leading to deterioration or malfunction of the engine. With the help of filters, these impurities are filtered out, which helps prolong an engine’s life span and boost its performance.

In this article, we will focus on alternative fuel filters. These filters remove contaminants from alternative fuels, which are defined as any fuel other than gasoline. According to the Energy Policy Act of 1992, all of the following are considered alternative fuels:

- Compressed natural gas (CNG)

- Propane

- Hydrogen

- Electricity

- Biodiesel

- Methanol

- Denatured ethanol

- P-Series fuels

CNG Filters

For a CNG vehicle to operate efficiently, the fuel system must be protected to keep the precision components and fuel injectors from failing prematurely.

When a CNG vehicle is filled up, the CNG is dispensed from the filling station into the fuel tank, at which point it enters the fuel injection system. However, contaminants — including lube oil from compressors, accumulation of solids during gas handling and condensed liquid in fuel tanks — can all negatively affect fuel system components. Therefore, these elements may require expensive and time-consuming repairs or replacements.

To prevent this unwanted situation, installing two filter types is key:

1. Coalescer

A coalescing filter should be installed upstream of the high-pressure regulator, which will prolong the system’s life and significantly lower maintenance costs. Coalescing elements are designed especially for removing liquid contaminants, like water and vapor. These contaminants flow from the element’s inside to the outside. Water and oil collect in the bowl where it’s drained, while gas or clean air leaves the housing via the outlet port.

To protect and extend the life of a coalescing filter, a particulate pre-filter is highly recommended. The retention of particulate contamination will extend the coalescing filter’s and regulator’s life cycles.

2. Low-Pressure Filter

A low-pressure filter can also be utilized downstream of the regulator. It protects other components of the fuel injection system to ensure successful operation. It accomplishes this by enabling hydraulic fluid to be filtered and blocking out particulates like sediment, silt and metal shavings that can affect system performance.

Alternative Fuel Filter Applications

Alternative fuel filters remove contaminants from alternative fuels like CNG, as well as air. Specific applications for these devices include the following.

High-Pressure Breathing Air

High-pressure breathing air is used in fire rescue equipment, scuba tanks, emergency respiratory equipment and various other applications. Filtering air for these uses is absolutely critical. Filtering processes and devices must meet strict air quality regulations set forth by the Occupational Health and Safety Administration (OSHA) and the Canadian Standards Association (CSA).

This is because contaminants in the air streams of these applications could lead to equipment malfunction and damage, which would require expensive replacements and repairs. Most importantly, it would also be hazardous for people using high-pressure breathing air apparatuses.

Using filters helps protect the users’ health and ensure the equipment is safe and operational. At the source of the compressed air, a coalescing filter removes oil and other liquid contaminants that otherwise may travel downstream. Once the compressed air reaches the point of use, it must be completely free of moisture, oil vapors, harmful tastes, odors and other impurities before the user can safely inhale it.

PET Blow Molding

Polyethylene terephthalate (PET) is a thermoplastic polymer resin used to manufacture various products, such as drink and food containers. These items are manufactured using a process called blow molding, which requires dry, clean air. The right filters will prevent pipe scale, compressor oils and other harmful impurities from accumulating on equipment.

CNG Fueling Stations

Before the gas travels from storage to a dispenser at a fueling station, two-stage coalescing will pre-filter out solids, water and oils generated during the underground transit. A high-efficiency coalescer should also be installed by the dispenser to provide delicate dispenser metering equipment with extra protection. This will also keep oil from getting into a vehicle.

Onboard CNG Vehicles

Filtration is essential to protecting against harmful contaminants that can destroy a fuel system. With the installation of a coalescer upstream from the high-pressure regulator, the system’s life span will be extended and maintenance costs will be lower.

Other Applications

Additional applications for alternative fluid filters include:

- High-pressure testing.

- Storage of high-pressure gas.

- Specialty gases.

- Corrosive gases.

- General high-pressure compressed air.

- Hydraulic equipment leak testing.

- Air-blast circuit breakers.

Chase Filters & Components Alternative Fuel Filters

At Chase Filters & Components, we offer a wide array of alternative fuel filters and components, making it easy for you to find the perfect filter for your application. Some of our more popular products — along with common alternative fuel filter features — include the following.

10 Series

With a maximum operating pressure of 250 pounds per square inch (PSI) and flow rates as high as 25 gallons per minute (GPM), the 10 Series Spin-On Filters come with numerous features for superior filtration. The particles that the 10 Series filter can remove are:

- Sand

- Fibers

- Sediments

- Iron

- Silt

- Dirt

- Metal shavings

The 10 Series filter has a temperature range that goes up to 250 degrees Fahrenheit. Other notable features include:

- Flows as high as 25 GPM (return).

- Flows as high as 9 GPM (suction).

- Port sizes ranging from 1/2 to 1 NPT.

- Gages to read differential pressure.

- Bypass options ranging from NON-bypass up to 25 pounds per square inch differential (PSID).

The 10 Series spin-on filters also serve numerous applications across various markets, such as:

- Chemical processing.

- Irrigation and agriculture.

- Mining.

- Gas and oil.

- Medical.

- Pharmaceutical.

- Food and beverage.

- Metalworking.

- Utilities.

11 Series

The 11 Series Spin-On Filters feature a maximum operating pressure of 250 PSI and flow rates up to 70 GPM. They remove fibers, sand, sediments and all the other contaminants that the 10 Series removes.

Some notable features of the 11 Series include:

- Elements that remove water and particulates.

- High-performing Micro Glass elements.

- Flows as high as 70 GPM (return).

- Flows as high as 25 GPM (suction).

- Temperature range as high as 250 degrees Fahrenheit.

- Port sizes between 1 and 1 1/2 NPT.

- Bypass options ranging between NON-bypass and 50 PSID.

- Gages to read differential pressure.

The 11 Series serves chemical processing, agriculture and all other industries that the 10 Series does.

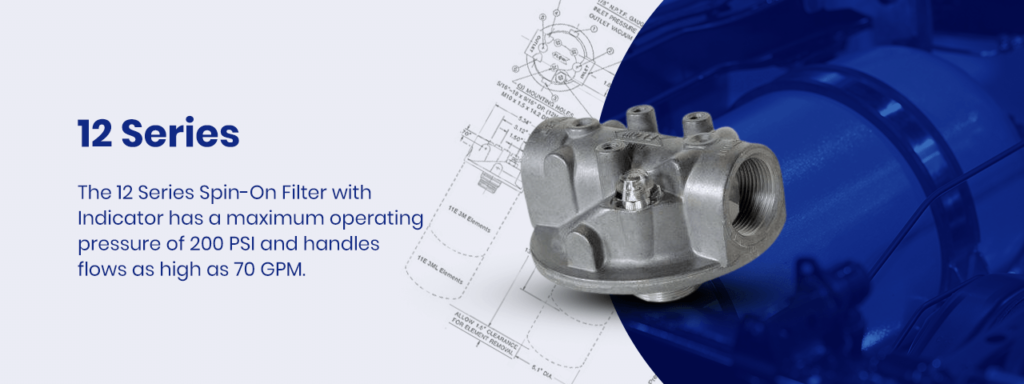

12 Series

The 12 Series Spin-On Filter w/ Indicator has a maximum operating pressure of 200 PSI and handles flows as high as 70 GPM. These low-pressure filters have several other useful features, which include:

- High-performing Micro Glass Elements.

- Elements that remove water and particulates.

- Temperature range as high as 250 degrees Fahrenheit.

- Flows as high as 70 GPM (return).

- Flows as high as 25 GPM (suction).

- Port sizes ranging from 1 to 1 1/2 NPT.

- Filter assemblies including electrical and visual indicators.

- Gages to read differential pressure.

13 Series

The 13 Series Modular Line Type Spin-On Filter comes with multiple spin-on filter head modules, which create a complete assembly. The multiple head design enables filter elements to be manifolded together. This, in turn, creates higher flow capacities and extends the filter’s life cycle. Additionally, the inlet flow divides equally between all the spin-on filter components.

Features of this filter series include:

- A 200 PSI maximum operating pressure.

- Flows as high as 120 GPM (return).

- Flows as high as 50 GPM (suction).

- An operating temperature range of up to 250 degrees Fahrenheit.

- Port sizes ranging from 1 1/2 inches for national pipe taper fuel (NPTF) to 2 inches for bolt flanges.

21 Series

The 21 Series Mini In-Line Filter is an economical option for applications including meters, test stands, relief, gauges, valves, hydraulic systems and pneumatic systems. It features stainless steel wire mesh discs, precision-pleated for increased filtration area and strength. This filter is great for applications where space is limited.

Some other notable features of the 21 Series include:

- Operating temperatures from minus 320 degrees to 550 degrees Fahrenheit.

- 304 Stainless Steel Pleated Disc.

- 304 Stainless Steel 1-Inch Hex.

- Special porting options.

- Cleanability.

- Quick delivery with various end connections.

31 Series

The 31 Series In-Line Filter does a great job of removing harmful particles from industrial equipment’s gas and oil streams and comes with the following benefits:

- It has a range of micron ratings.

- It can operate at pressures as high as 6,000 PSI.

- It features a stainless steel housing.

- It’s available in 303, 316 and 17-4PH.

41 Series

The 41 Series Mini Tee-Type Filter removes unwanted harmful particles including dirt, scale and rust. This filter can operate at pressures as high as 10,000 PSI, has a broad range of micron ratings and is equipped with 316 and 17-4PH stainless steel housings.

51 Series

We offer our 51 Series T-Type filters at 6,000 PSI operating for stainless steel filters and 5,000 PSI Operating Aluminum. These useful high-pressure filters separate and remove damaging contaminants from the fluid to ensure your systems operate as efficiently as possible. Contaminants removed by these filters include scale, rust and dirt, keeping your fluid contaminant-free.

T-Type filters like the Chase 51 Series are useful in a broad range of industrial, manufacturing and commercial industries. Markets they serve in addition to alternative fuels include:

- Cryogenics.

- CNG.

- Aviation ground support.

- Petrochemical.

- Aerospace.

- Test stand builders.

- Mining.

- Helium.

- Hydrogen.

- Extraction.

- Lubrication fluids.

- Industrial equipment.

- Industrial automation.

- Military shipboard.

- Power generation.

- Power unit.

- Oil field services.

- Paper and pulp.

- Robotics.

The 51 Series T-Type filters boast a vast array of impressive features, which help the design achieve a high level of functionality and performance. Features include:

- 316 or 303 stainless steel construction options.

- Differential pressure (DP) indicator availability.

- Bowl drain options.

- A wide range of micron ratings.

- A broad variety of O-ring possibilities for custom alternative fuel filter applications.

52 Series

The 52 Series T-Type Filter features 17-4PH stainless steel housings for 20K and 303 or 316 stainless steel housings for 10K. Other features and configuration choices for the 52 Series include:

- Micron ratings ranging between 0.1 and 150.

- Flows as high as 24 GPM or 1,200 SCFM.

- Options to choose between stainless steel, porous sintered stainless steel, micro-glass and fiber metal felt for elements.

- Port sizes ranging from 1/4 to 3/4 inches FNPT for 10K only.

57 Series

The filter’s C-grade element consists of an inner and outer borosilicate microfiber layer:

- Inner layer: The inner layer consists of extremely fine fiber that is packed more densely to catch microscopic aerosols.

- Outer layer: The outer layer consists of slightly bigger fibers that allow the caught liquids to pass through the wall’s depth and drain off the element.

Coalescing elements must always flow from the element’s inside to the outside, which allows for the proper drainage of liquids. These elements collect particulates simultaneously.

Stainless steel housings all come with Viton® seals — which provide chemical resistance — and a coalescing filter element to begin separating gas and water droplets and aerosols.

Our 57 Series stainless steel filters all have CS-grade elements designed to promote heavy coalescing and withstand temperatures as high as 900 degrees Fahrenheit. The filters come with a silica binder instead of a standard C-grade polyvinylidene fluoride (PVDF) binder, which makes them better for high-temperature environments because of their reactivity and large surface area.

Our stainless steel air filters also boast an impressive 95% micron removal rate.

Alternative Vehicles Need High-Pressure Filtration

CNG is one of the automotive industry’s most popular alternatives to traditional fuel. CNG provides fuel for passenger vehicles, pickups and school buses. It’s cheaper than gasoline and more eco-friendly, as it produces fewer CO, CO2 and hydrocarbon vehicle exhaust emissions.

Natural gas comes from a pipeline and goes to a connecting compressor station, where it is increased to pressures between 2,000 and 5,000 pounds per square inch in gage (PSIG) and stored in tanks. These tanks then make their way to gas dispensers, where natural gas vehicles can use them.

However, during this multi-step process, it is easy for contaminants to get into the gas. Contaminants can enter the CNG supply in various ways, including handling tasks, compressors leaking oil into the fuel supply or water condensing in tanks. All of these problems can shorten the life span of pricey equipment, unnecessarily disrupt operations and increase maintenance costs.

For this reason, filters are absolutely necessary during every stage of the process to make sure the gas is clean at the end.

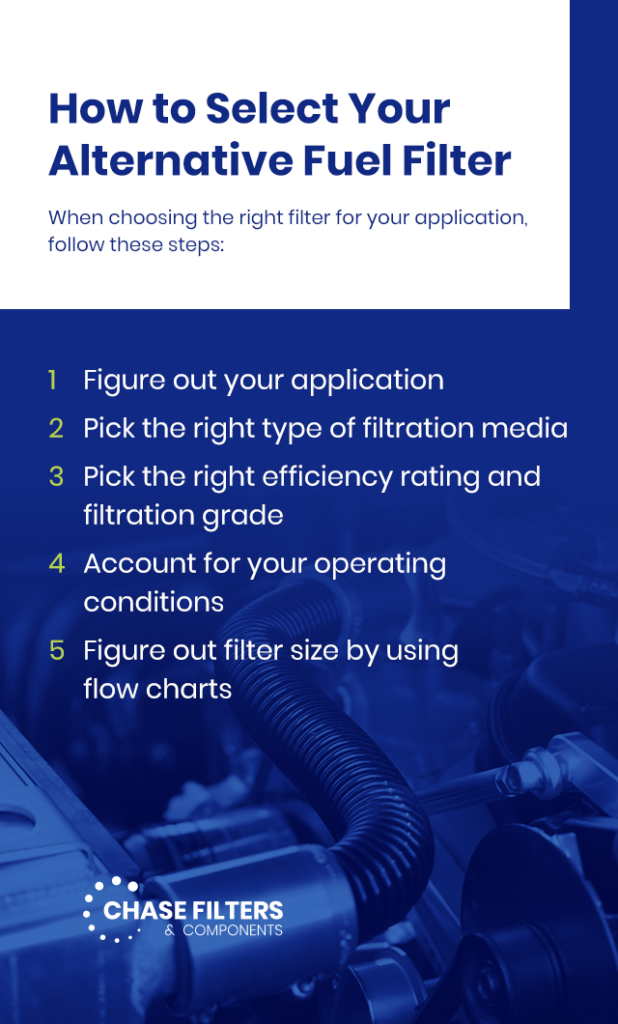

How to Select Your Alternative Fuel Filter

When choosing the right filter for your application, follow these steps:

- Figure out your application: Determine what exactly your application requires, including what kinds of particulates will need removal.

- Pick the right type of filtration media: What kind of filtration do you need? For example, coalescing filter media removes the liquid and solid contaminants from a gas stream. To remove hydrocarbon vapors from a gas stream, you’ll want absorber media.

- Pick the right efficiency rating and filtration grade: If you’re looking for a particular efficiency or micron rating, learn about filter media grades and how they perform.

- Account for your operating conditions: What operating conditions does your application have? Important factors to think about are temperature, pressure, flow and construction materials, such as nylon, stainless steel, aluminum and more.

- Figure out filter size by using flow charts: Flow charts are provided for all high-pressure filter series, with flows listed at various operating pressures. You can find filters with pressure ratings as high as 6,000 PSIG and flows as high as 6,500 standard cubic feet per minute (SCFM).

Benefits of Alternative Fuel Filters

While you’re likely well aware of how useful alternative fuel filters are at this point, you may not know about all the benefits they provide. These include:

- They prevent pipeline dust and sand from entering a gas plant facility.

- They make sure fuel is clean before it’s burned in an engine or heater.

- They lower the amount of foaming in a glycol or amine contactor.

- They help water disposal wells prevent reservoir plugging.

- They extend the life of pump impellers in hot oil systems.

- They significantly reduce nozzle plugging in instrument controllers.

Contact Chase Filters & Components for Alternative Fuel Filters

For dependable, high-performance filters, Chase Filters & Components is the alternative fuel filter manufacturer you want. For over 30 years, we have been making a vast selection of filters for gas and air for all our customers’ filtration needs. Our versatile products are resistant to corrosion and withstand wide pressure ranges and extremely high temperatures. In addition to selling the highest-quality products in the industry, we also strive to provide excellent customer service and quick turnarounds.

If you would like to learn more about our products, feel free to browse our products page or get in touch with us using our contact form.