Aerospace Filters

Both aircraft and spacecraft rely on filters every day to ensure safety and avoid suffering damage while in flight. Without filters, neither would be able to fly for extended stretches without needing to be grounded for repairs or having launches face major delays. A lack of filtration can also cause whole systems to fail, resulting in catastrophic accidents. Given the importance of filters, many companies that own any type of aircraft or spacecraft ensure they outfit their fleet with the best filtration possible.

As you look for aerospace filters, learn more about their many applications, top features, benefits and the primary industries they serve.

Contact Us for Aerospace Filters

Aerospace Filter Applications

There are many applications for aerospace filters, and you can find them in various systems to help the craft function at a top level. Some common aerospace filters include:

- Hydraulic filters

- Pneumatic filters

- Breathing filters

- Oxygen filters

- Coolant filters

- Fuel filters

- Air filters

- Oil filters

- Water filters

Aerospace hydraulic filters strain and screen hydraulic fluid to ensure it’s clean. They safeguard a hydraulic system from contaminating substances and particles that could cause it to fail. Aerospace fuel filters help remove contaminants from fuel and deliver clean fuel to the engine. By delivering clean fuel to the engine, they reduce wear on the pump and injector.

Aerospace air filters are especially important to aircraft, as clean air is needed in the cabin while they’re in motion. These filters protect the cabin’s air quality by stopping harmful allergens, fibers, microbes and dust from entering the air.

Oxygen filters play a critical part in both aircraft and spacecraft in terms of supplying clean oxygen to the crew and pilots. They can also supply clean oxygen to airline passengers in critical cases. Oxygen filters also play a key part in ground support as many systems utilize oxygen.

Chase Filters & Components Aerospace Filters

Chase Filters & Components offers several aerospace filters for various applications to help your aircraft run at peak efficiency, with our 25 Series, 31 Series and 51 Series being the most popular.

25 Series

The 25 Series aerospace filter is a high-pressure oxygen filter. These patented filters protect critical equipment in all of these critical applications. Contaminants like rubber, dust and rust can all damage your equipment and pose a health hazard if used in a critical breathing application. By utilizing 25 Series oxygen filters, you can greatly reduce the chances of impurities causing ignitions and can keep your operations clean and safe while utilizing these filters in manned space flight and in breathing air applications.

The 25 Series has passed the rigorous ASTM G-175 Phase 2 Promoted Ignition Test. This test shows that the 25 Series oxygen filters are fault-tolerant and ignition resistant. As a result, you can expect them to contain ignition events, protecting system components and downstream piping.

31 Series

We’ve designed our 31 Series in-line filters to keep harmful contaminants out of your fluids. By ensuring your fluid is clean with a filter, you prevent contaminated hydraulic fluids from harming your system’s performance.

The high-pressure nature of these filters makes it so contaminants, like rubber, sand, fiber, silt, dust and metal shavings, stay out of your system. A major benefit of using 31 Series in-line filters is that you can extend your equipment’s life span and reduce the amount of maintenance you have to perform.

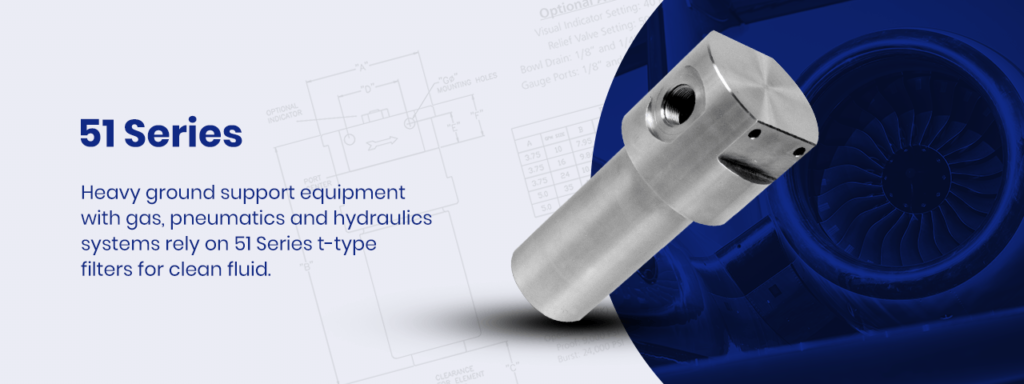

51 Series

Heavy ground support equipment with gas, pneumatics and hydraulics systems rely on 51 Series t-type filters for clean fluid. These t-type filters keep contaminants out of the fluids and ensure your machinery and systems run smoothly. You can find these filters ranging from 5,000 PSI all the way up to 60,000 PSI, with many options in between. The wide variety of O-ring possibilities and micron ratings make them well-suited for different uses.

Contact Us for Aerospace Filters

Aerospace Filters for Defense Industry

The defense industry utilizes filters in multiple types of aircraft, ships and Navy diving. Military jets, cargo planes and helicopters need filters to ensure every component runs at a top level. In the defense industry, filters are built for spacecraft, launch pads, space suits, testing and ground support.

Fixed-wing aircraft, such as surveillance planes, fighters, transport aircraft and bombers, all require filtration to ensure they’re ready to perform. A fixed-wing aircraft needs to be ready at a moment’s notice and deliver reliable performance for a mission to succeed. Like other machines, military fixed-wing aircraft utilize fluid systems that can be contaminated. This contamination can corrupt the aircraft’s parts, causing malfunctions and possibly total system failure. Filters reduce the amount of maintenance that has to be performed on a fixed aircraft, saving time and money.

Rotary aircraft, such as attack and transportation military helicopters, also rely on aerospace filters to ensure they can fly safely and perform their best. These rotorcrafts support tactical airlifts, search and rescue operations, intelligence, surveillance and reconnaissance functions.

Since helicopters require rotary wings to fly, they need unique filters to function properly. Filters help protect military helicopters in the harshest conditions and climates, with filters stopping airborne contaminants from harming components and fluid systems. The filters offer separation and filtration capabilities to ensure a military rotorcraft can meet any challenge. Without the right filters, important aircraft systems can be contaminated, leading to damage that would cause the aircraft to be grounded. In critical operations, inoperable helicopters aren’t acceptable, making the right filters crucial.

Aerospace filters for military applications meet the strictest regulations and feature reliable filtration abilities. Since they keep contaminants out of essential systems, they improve a helicopter’s performance, increase safety, lengthen the life span of equipment and reduce maintenance costs.

Filters for Commercial Aerospace Application

In addition to filters’ use in the defense industry, filters for commercial aerospace applications are also very popular. Like the defense industry, those in the commercial aerospace sector rely on filters for all their critical applications.

Chase Filters & Components has been an industry leader for the last 10 years by supplying both custom and off-the-shelf items to the aerospace sector. Since we follow the most stringent of specifications for both manned and unmanned aircraft, Chase Filters & Components is on the cutting edge of design in the ever-changing, exciting commercial space market.

Ground support applications:

- Fueling and fueling services

- Oxygen services

- Cryogenic

- Hydraulic services

Manned and unmanned spacecraft:

- Oxygen services for breathing air

- Propulsion

Custom Filters for Aerospace Applications

Many customers rely on custom filters when a system has nonstandard dimensions or specifications not seen in typical off-the-shelf items. Custom filters may also be required when a system is old and components may be difficult to find.

Working with a company that can design and build a custom filter makes it possible for your system to run at its best while not settling for a filter not built for your specific need. Custom filters ensure your system or vehicle runs properly and stays free of contaminants, while also reducing your maintenance expenses, downtime and chance of system or vehicle failure.

When you order a custom filter from Chase Filters & Components, you will love how we handle short-run orders for companies that need only a limited amount of filters – unlike many other aerospace filter manufacturers that won’t. Additionally, Chase Filters & Components provides specialty machining to craft unique products in an economical and fast manner.

Aerospace Filter Features

Top-quality aerospace filters come with various features ensuring they deliver the best results and protection. Finding a filter that comes with the right features is crucial for your company. Check out the following features you may want in an aerospace filter:

- High-quality materials: Aerospace filters need to resist corrosion and damage. As such, filters with stainless steel, aluminum, brass, Monel, Inconel and titanium are a great choice. These materials, along with others not mentioned, are compatible for most applications with both fluid compatibility and weight concerns.

- Various micron ratings: Different applications are going to rely on different micron ratings. Chase Filters & Components offers a variety of micron ratings along with several material options to suit your most critical needs.

- Different PSI ratings: Like the need for varying micron ratings, it’s also important for a filter to allow for different PSI ratings. With the ability to offer filters all the way up to 60,000 PSI, Chase Filters & Components has all your needs covered.

Contact Chase Filters & Components for Aerospace Filters

As a top aerospace filter manufacturer with over 50 years of experience in the industry, Chase Filters & Components is ready to provide your organization with high-quality filters meeting all your critical needs.

Browse our selection of filters and products. If you need help finding the best aerospace filter for your aircraft, contact us today.