Thank you for checking out our products

We offer a variety of high pressure filters for air, oxygen, gas, hydraulic fluid, engine lubricant, fuel, and water.

Oxygen Filters

Oxygen Filters

Oxygen filtration is vital for delivering a safe, consistent oxygen supply that complies with oxygen or breathing air purity regulations. Besides filtering the air, oxygen filters protect systems from potentially harmful contaminants that often cause malfunctioning or long-term damage.

At Chase Filters & Components, we offer an extensive range of filters that work well for nearly any oxygen system. We provide the products you need to improve safety and increase process efficiency in your work environment.

How Does Oxygen Filtration Work?

Oxygen filters trap the particulates and harmful contaminants that generate within your system or enter from the outside, ensuring smooth and efficient operation while preventing these contaminants from harming key system components. Keeping your system clean of debris will help eliminate ignition or fire risk.

Even though filters serve a comprehensive application range — from aerospace and mining to manufacturing facilities and testing labs — they all function similarly, blocking particulates and contaminants to maintain a fresh oxygen supply. The primary role of the filters is to maintain system efficiency while delivering a clean oxygen supply.

Types of Oxygen Filters and Oxygen Filter Elements We Offer

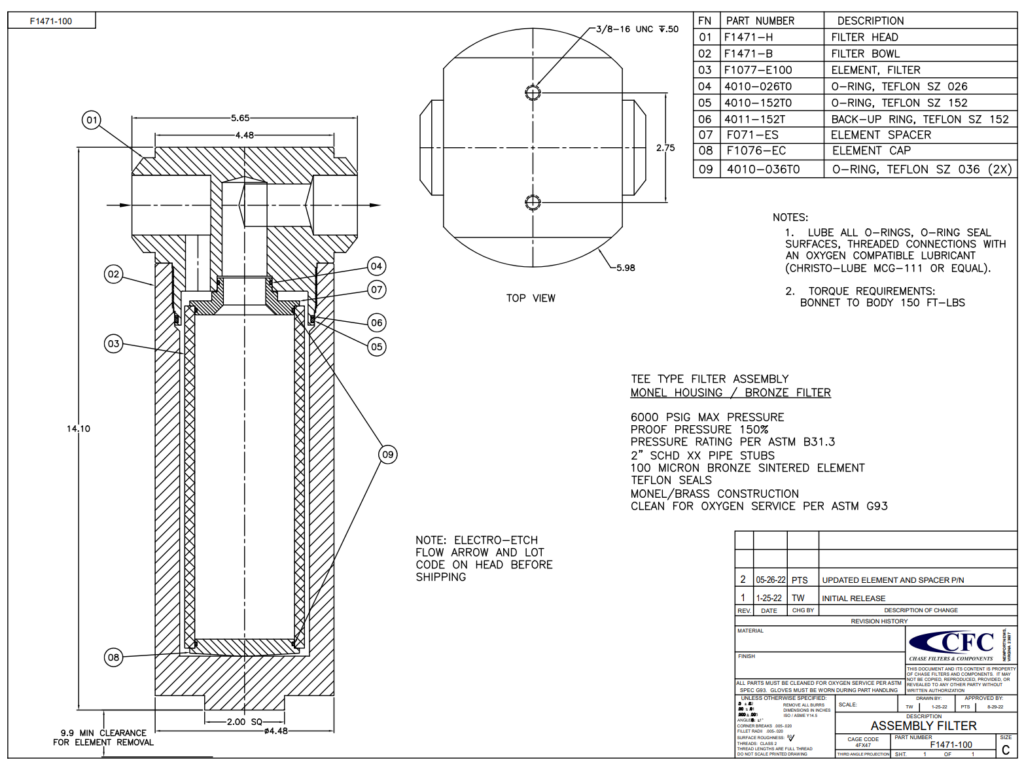

Chase Filters & Components is among the industry’s leading manufacturers, offering various oxygen filter designs for specific uses. We use premium brass, Monel and sintered bronze materials to ensure high-performing functionality and long-lasting durability. Some filter types we offer include:

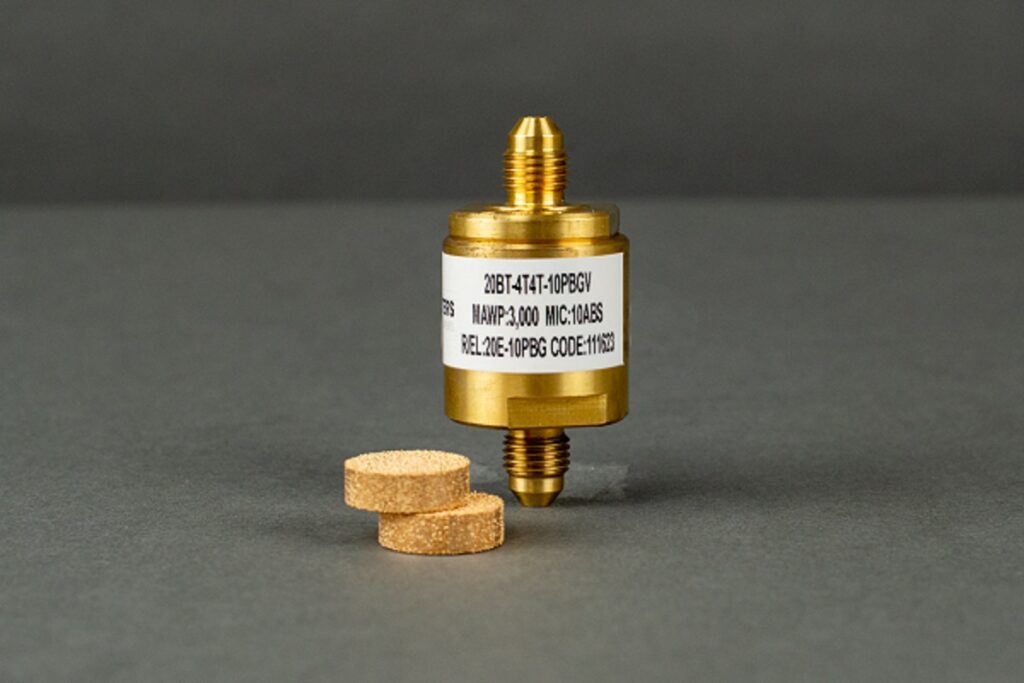

- In-line filters: Our in-line filters remove contaminants from high-pressure systems with limited space, preventing damage to all critical components. These filters are perfect for corrosive environments and can catch heavy, bulky particulates like dirt, metal and rust.

- Tee-type filters: Our tee-type filters are ideal for oxygenThey trap contaminates to ensure a clean working oxygen system and help prevent any oxygen fire ignition. Their design allows easy removal and element replacement without disconnecting the filter housing.

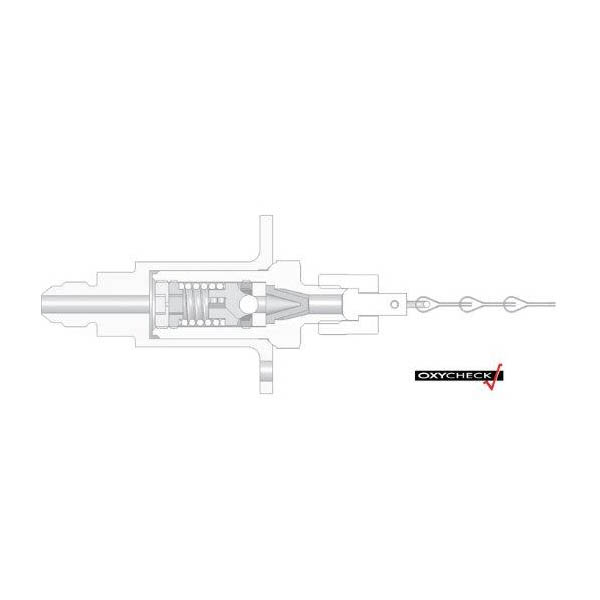

- OXYCHECK valves: Our OXYCHECK components are nonflammable and offer an extra element of security and protection against fire and spark ignition, resulting in the highest possible safety levels for commercial and industrial applications.

Most of our filters are highly adaptable and offer quick installation. We also provide filters with multiple micron ratings and customizable end fittings to meet your needs.

Oxygen Safety

Oxygen, heat and fuel are necessary for a fire to burn. Oxygen systems are unique — removing any of these elements is typically impossible to maintain a fire.

Oxygen Reactivity

Oxygen behaves differently than regular air, compressed air, nitrogen and other inert gases due to its reactivity. Any mechanism that releases heat can start a fire in an oxygen system. Common materials, like stainless steel or aluminum, readily support burning and can result in catastrophic circumstances in pressurized or concentrated oxygen systems.

Because of these potential dangers, only competent personnel with specialized knowledge should design, construct, install and commission oxygen systems. A fire can occur with an incorrect installation or when improper components and materials are present in these systems. Fires in oxygen systems release considerable amounts of energy and can often spread into surrounding structures, making component failures more destructive.

Fire Control

Chase Filters & Components uses materials that are nonflammable in oxygen at pressures equal or greater than the maximum allowable working pressure. These specific components remove the fuel portion of the fire triangle, reduce the chance of a fire occurring and minimize the risk of accidental ignition. This rigorous engineering process results in oxygen system components with unprecedented safety levels.

At Chase Filters & Components, we design, test and verify our filters to contain an ignition event without breaching the filter element or body. These processes protect the piping and system components while reducing the likelihood of ignition.

Testing Methodology

Although filters are critical for capturing and trapping contaminants, maintaining cleanliness and minimizing downstream ignitions, they are still subject to risk and hazards if not constructed, tested, installed and maintained correctly.

Potential dangers include the following:

- Accumulated flammable particles and lubricants.

- Clogging from poor design or improper maintenance.

- Incorrect cross-section construction and ineffective burn resistance.

- Poor construction creating regions with high velocities and turbulence, causing particle impact and tribocharging hazards.

No formal testing for filters exists, even though many applications use a potentially flammable metal configuration. Chase Filters & Components approached the World Health Assembly (WHA) — the governing body of the World Health Organization (WHO) — to develop a test demonstrating the importance of oxygen filter material selection and design. The test addresses several potential ignition mechanisms, including particle impact, kindling chains and the adiabatic compression of contaminants.

The approach involves applying a forced-ignition event upstream to a contaminated filter and determining whether it safely contains the event without external fire, pressure breach or fire propagation past the filter element. Chase Filter & Components evaluated two filter designs with different materials — a stainless steel design that failed and a brass filter that safely contained the promoted ignition.

Chase Filters & Components is currently developing a testing method for determining the standard quantity of contamination and plans to propose the procedure to the ASTM G4 committee for consideration.

Purchase Oxygen Filters at Chase Filters & Components Today

If you’re looking for a reliable and efficient oxygen filtration solution for your application, you’ve come to the right place. Our knowledgeable team has decades of experience helping customers find the perfect solutions for their unique systems. To learn more about our oxygen filtration products and how they can benefit your operation, contact us online or call 757-505-7949 today.