Product

Grounding Rings

Product Details

Product Features

Electromagnetic Flow Meters and Grounding Rings

Electromagnetic flow meters — also known as mag meters — offer a noninvasive and reliable way to check flow rates in conductive liquids like water and hydrochloric acid. They are essential tools in industries that rely on accurate fluid measurement, including municipal water systems and chemical processing plants.

Mag meters are used for accurate flow data, and grounding rings are key to maintaining it. Grounding rings may be small, but their impact on accurate measurements is massive. They enable signal stability, reduce electrical noise, and protect against erratic flow readings.

Explore what mag meters and grounding rings are, why they’re essential, how they work and how to install them.

What Are Electromagnetic Flow Meters?

Electromagnetic flow meters measure the volumetric flow rate of a conductive liquid moving through a closed pipe. Mag meters measure the flow of conductive fluids through a magnetic field, as they generate a voltage proportional to their velocity.

The mag meter’s pipe section is smooth and empty inside, allowing fluid to flow easily and without obstruction. Mag meters also don’t have moving parts that rotate, spin or oscillate within the pipe, which means they have a long service life and only require minimal maintenance. Even in turbulent conditions, magnetic flow meters can accurately measure flow rates. These advantages make them ideal for applications involving dirty, corrosive or viscous fluids, like wastewater treatment.

To function properly, mag meters require a conductive fluid and a stable electrical ground. Without proper grounding, the voltage signal generated by the fluid can become distorted, leading to inaccurate readings and unreliable data.

Why Electrical Grounding Is Essential

Electrical grounding is the foundation of accurate mag meter performance because the voltage signal generated by flowing conductive fluids is weak. Any interference that could affect this signal can also result in erratic readings.

Poor grounding can cause signal instability and drift, electrical interference from nearby equipment, and inaccurate measurements. A robust and proper mag meter grounding strategy prevents these issues by providing a stable reference point, ensuring that the fluid, electrodes and transmitter share the same electrical potential. Appropriate electrical grounding with a mag meter minimizes voltage differences that can introduce electrical noise and corrupt the mag meter’s signal.

An effective way to achieve proper grounding is to integrate grounding rings into the piping system.

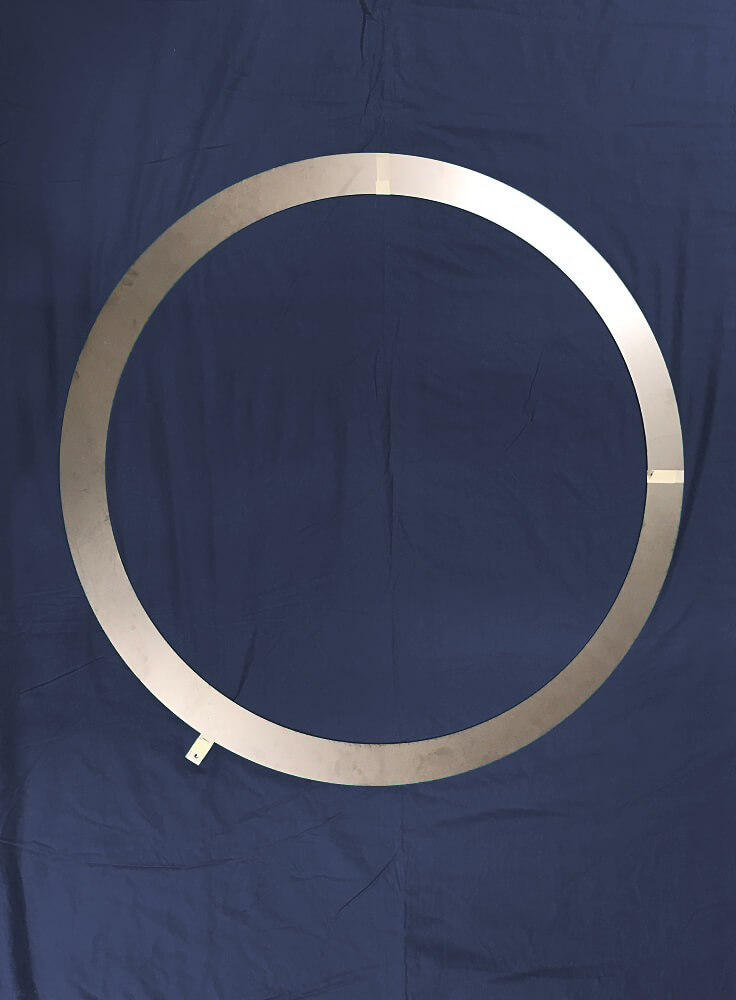

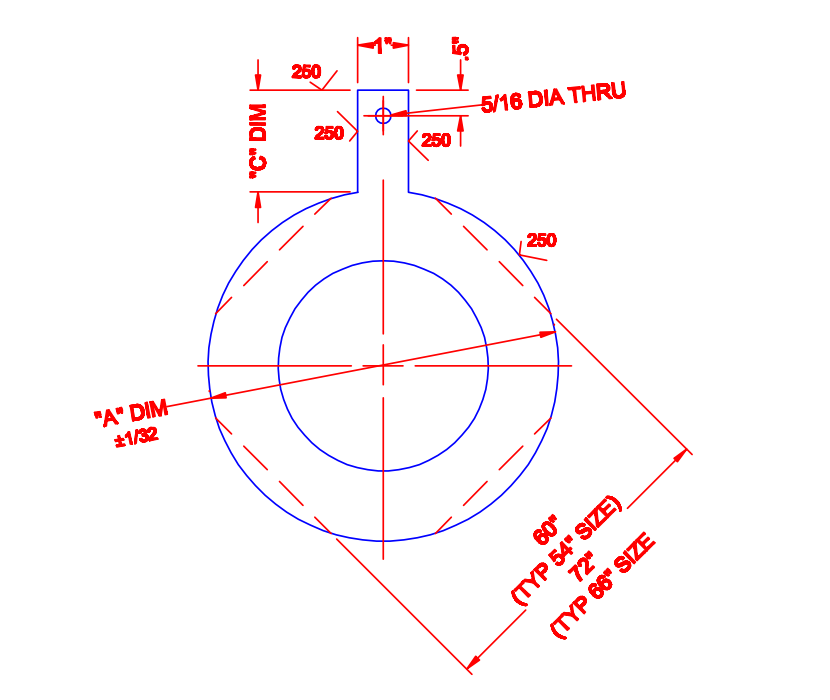

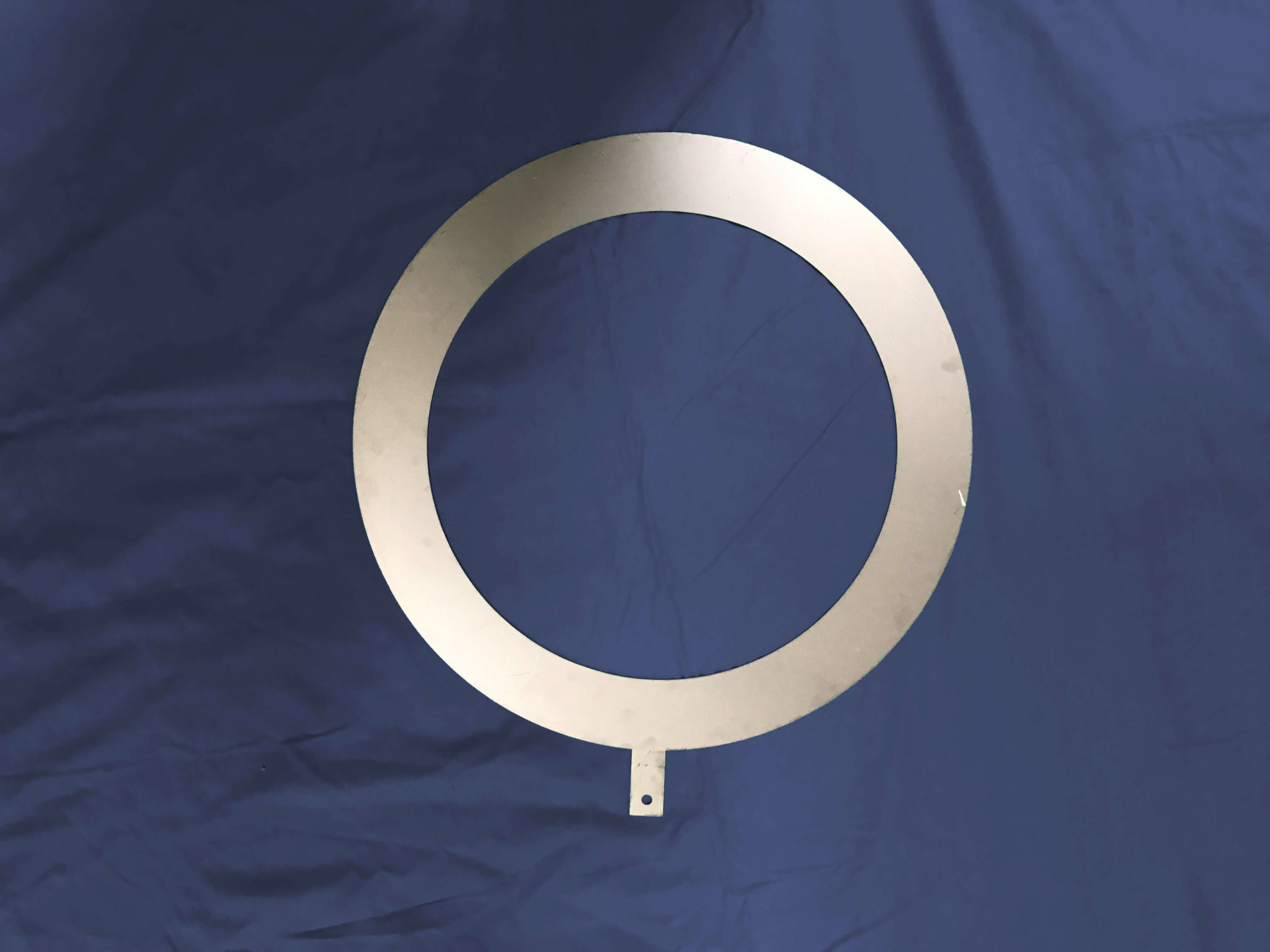

What Are Grounding Rings?

A grounding ring is a conductive device used in electrical grounding to suppress noise or protect against surges. Common types of grounding rings include:

- Shaft grounding ring: This type prevents electrical discharge damage to bearings in rotating equipment, particularly electric motors

- Flow meter grounding ring: This ring supports a steady and consistent electrical potential between conductive fluids and the mag meter

Flow meter grounding rings are metallic components installed between the flow tubes and flanges of mag meters. They provide a secure electrical path between the process fluid and the transmitter. Grounding rings are especially beneficial in plastic piping systems, as nonconductive materials limit standard electrode contact with the process fluid. The rings are also effective in manufacturing plants, mines and other environments with high electrical noise.

Choosing the right grounding rings for your business or organization will depend on the specific application, environment, equipment and piping material. You should also consider the type of grounding ring material:

- Stainless steel: Durable and corrosion-resistant, stainless steel is suitable for industrial water, tap water, sewage, treated wastewater, and weak acids, such as carbonic acid or acetic acid.

- Hastelloy: Suited for harsh industrial conditions like aggressive chemical processing, hastelloy is resistant to high temperatures, high chloride concentrations, and strong acids, including hydrochloric acid and sulfuric acid.

- Titanium: Lightweight, compatible with many pipe materials, and ideal for seawater and marine environments, titanium is highly resistant to chlorides, hypochlorites, and oxidizing acids, like nitric acid and chromic acid.

Why Mag Meter Grounding Rings Matter

Mag meter grounding rings ensure accurate and reliable flow rate readings. By supporting consistent data, they help protect equipment and improve process controls.

Use grounding rings when:

- Your piping is made of a nonconductive material, like PVC, or has a nonconductive lining, such as PTFE or rubber, which prevents direct electrical contact with the fluid.

- The process fluid has low electrical conductivity, making it difficult to establish a stable ground reference through standard electrodes.

- Optimal electrode contact with the process fluid is limited, leading to unstable or noisy signals.

The benefits of grounding rings include:

- Stable signal transmission and improved measurement accuracy

- Reduced electrical interference and noise

- Extended lifespans of mag meters

Grounding rings also safeguard against temperature variations, voltage surges and other unpredictable conditions. Your mag meter will deliver consistent, trustworthy data — no matter what your system throws at it.

Best Practices for Installation

Proper installation is key to maximizing grounding ring performance. Follow these best practices to avoid stability issues, signal degradation and potential equipment damage:

- Use compatible materials: Match the grounding ring’s material to both the process fluid and pipe flange material. This consideration can prevent corrosion or galvanic reactions that can compromise the grounding path.

- Install on both ends of the mag meter: Place grounding rings on both upstream and downstream flanges for balanced signal grounding. Using rings in both places will also minimize the effects of external electrical noise.

- Secure tight contact with the flange and fluid path: The grounding rings should sit flush against the mag meter flange and flow tube. This placement maintains stable electrical connections and signal integrity.

- Conduct regular inspections: Check the rings for wear, corrosion or buildup of nonconductive materials that could compromise conductivity. Keeping the grounding rings in good condition will ensure continued grounding effectiveness and reliable mag meter performance.

Contact Chase Filters & Components for High-Quality Grounding Rings

Source your components from a trusted manufacturer. At Chase Filters & Components, we understand that accuracy starts with the details.

Whether you’re designing a new system or upgrading an existing mag meter, our selection of grounding rings is engineered to meet demanding process conditions and installation standards. Built for durability, conductivity and long-term performance, they ensure your system performs at peak condition from day one.

Request a quote today to learn more about our high-quality grounding rings.